Original Handcrafted Knives

Referred by a friend?

Let us know and you’ll save 10%!

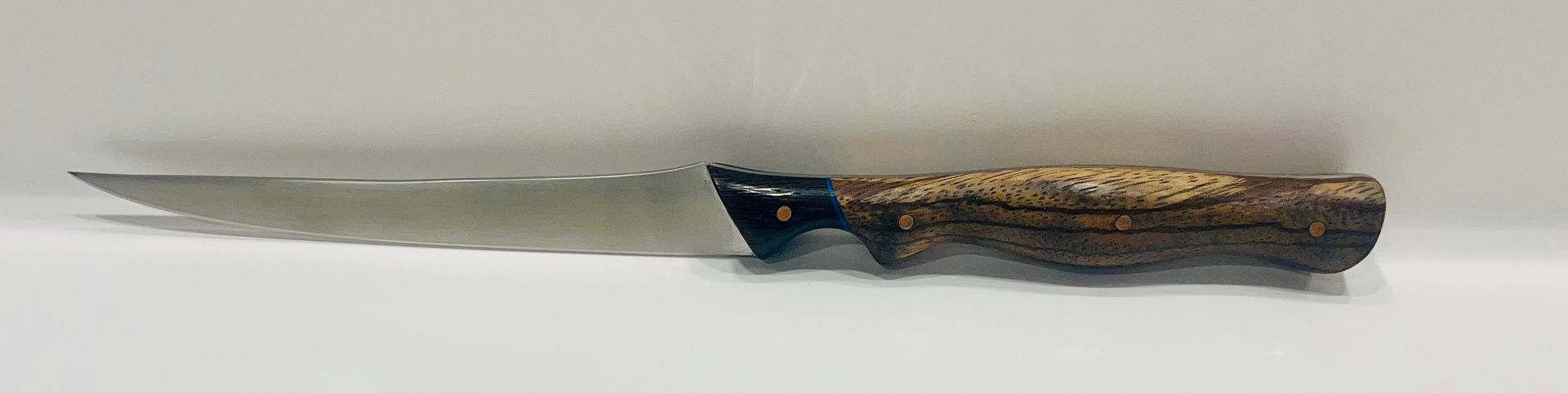

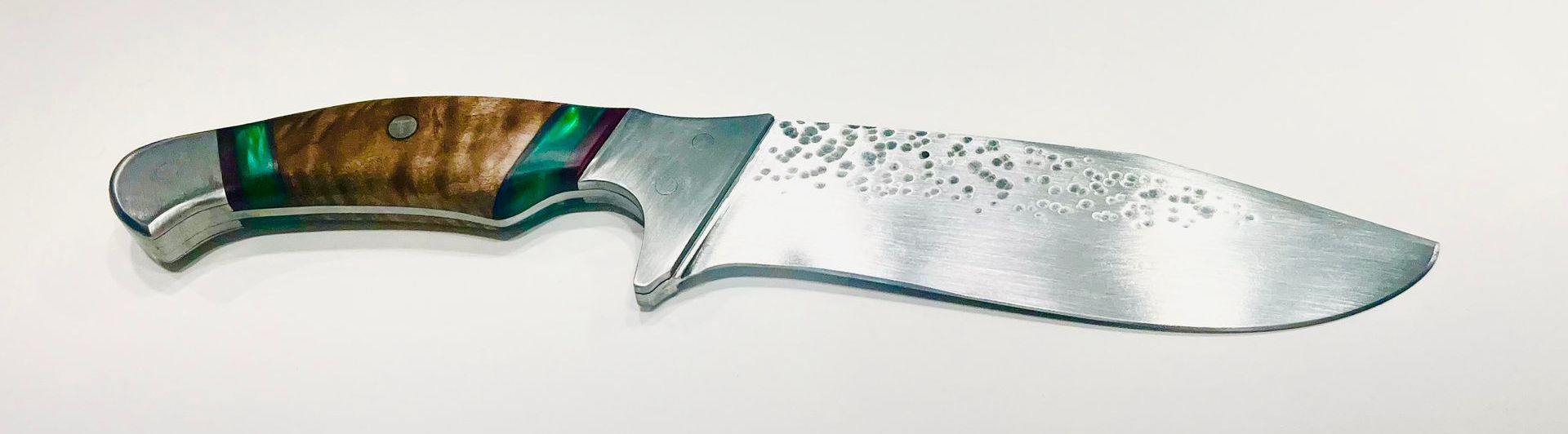

Excalibur Camp Knife

7" E52100 High Carbon Steel Blade

Bloodwood Handle with Blue & White Acrylic

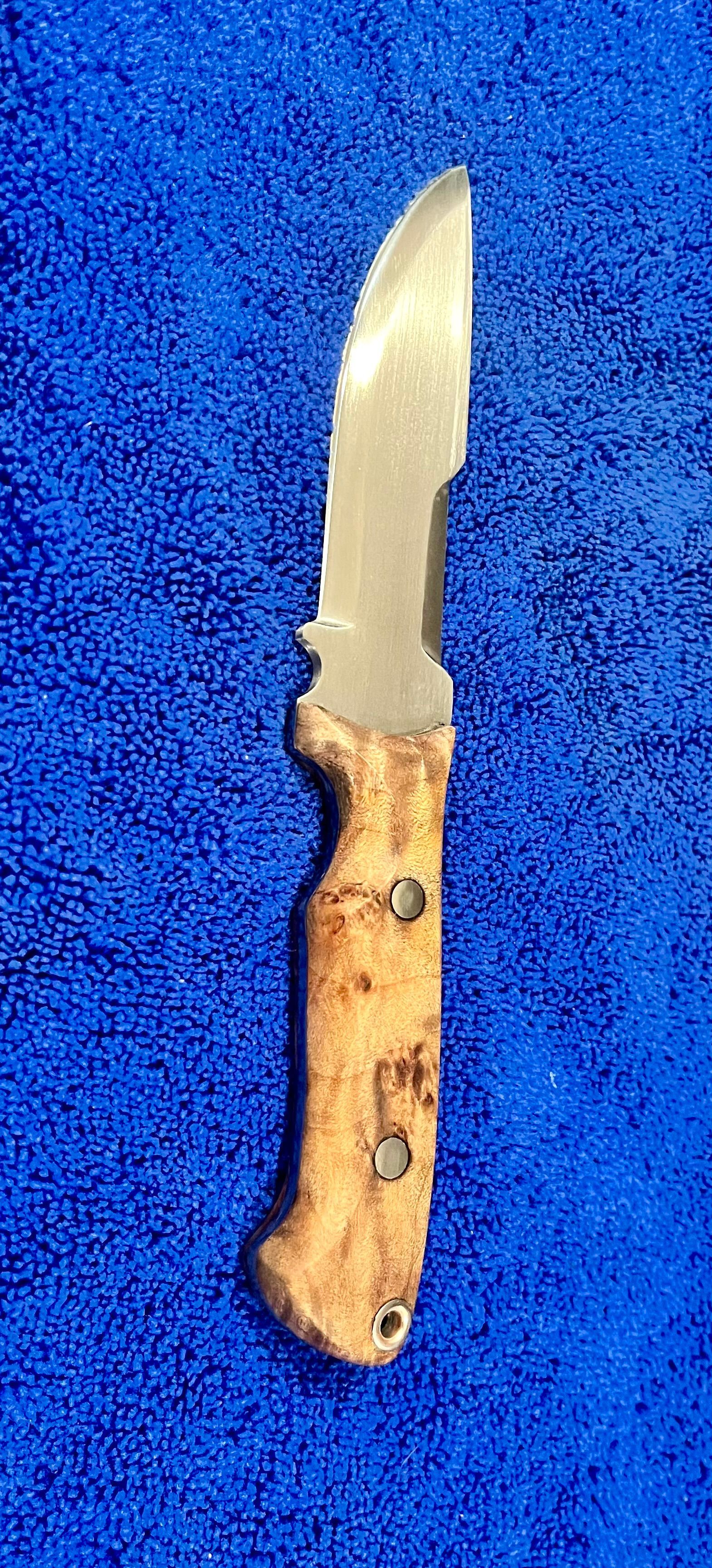

Yellowstone

Straight Back Skinning Knife

4" 80CRV2 High Carbon Steel Blade

Satin Finish

Walnut Burl Handle with Jimping

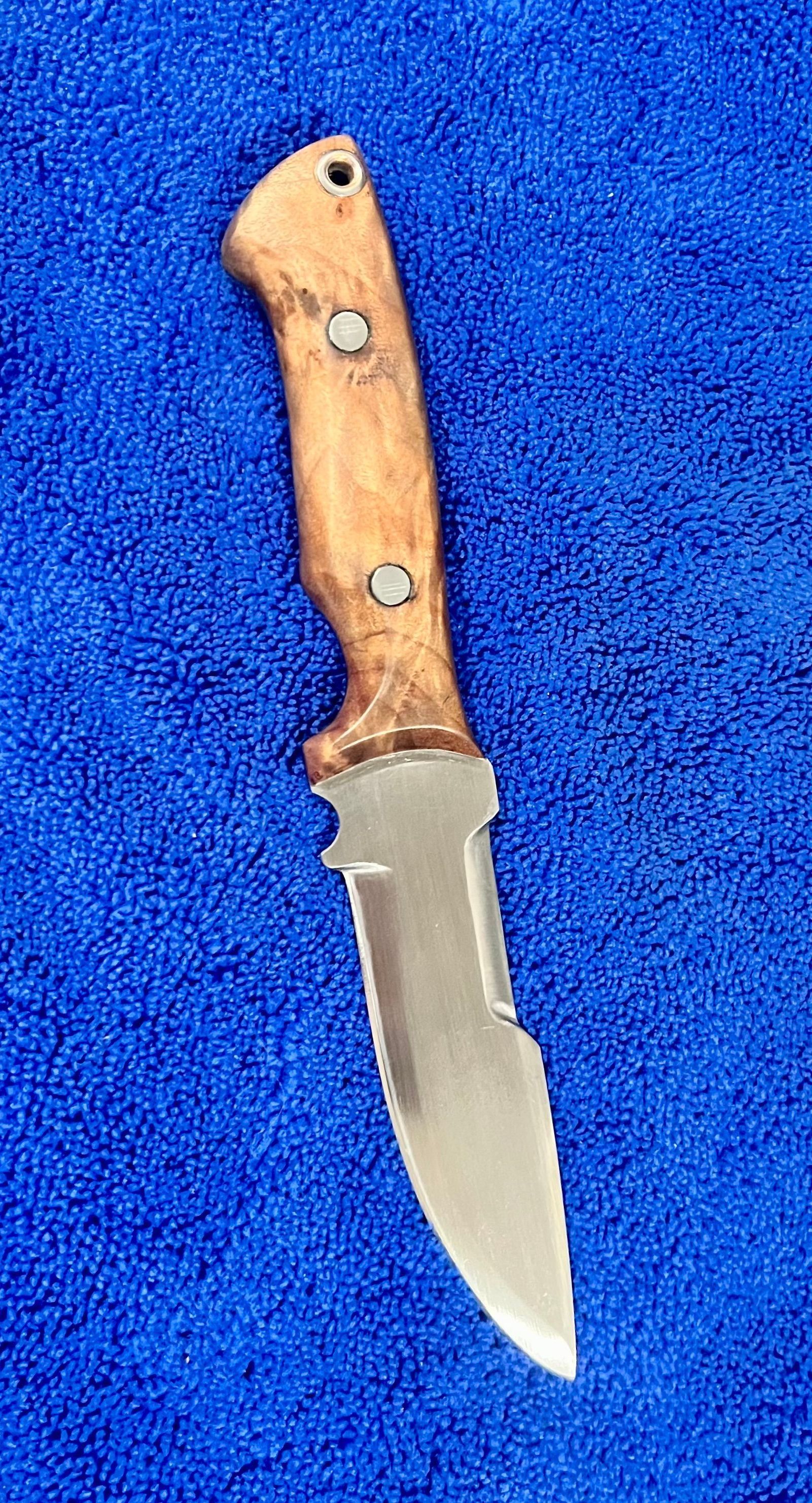

4" Bobcat Skinning Knife

4" E52100 Blade High Carbon Steel

Blue-Green Paracord Wrapped Ring-Tail Handle

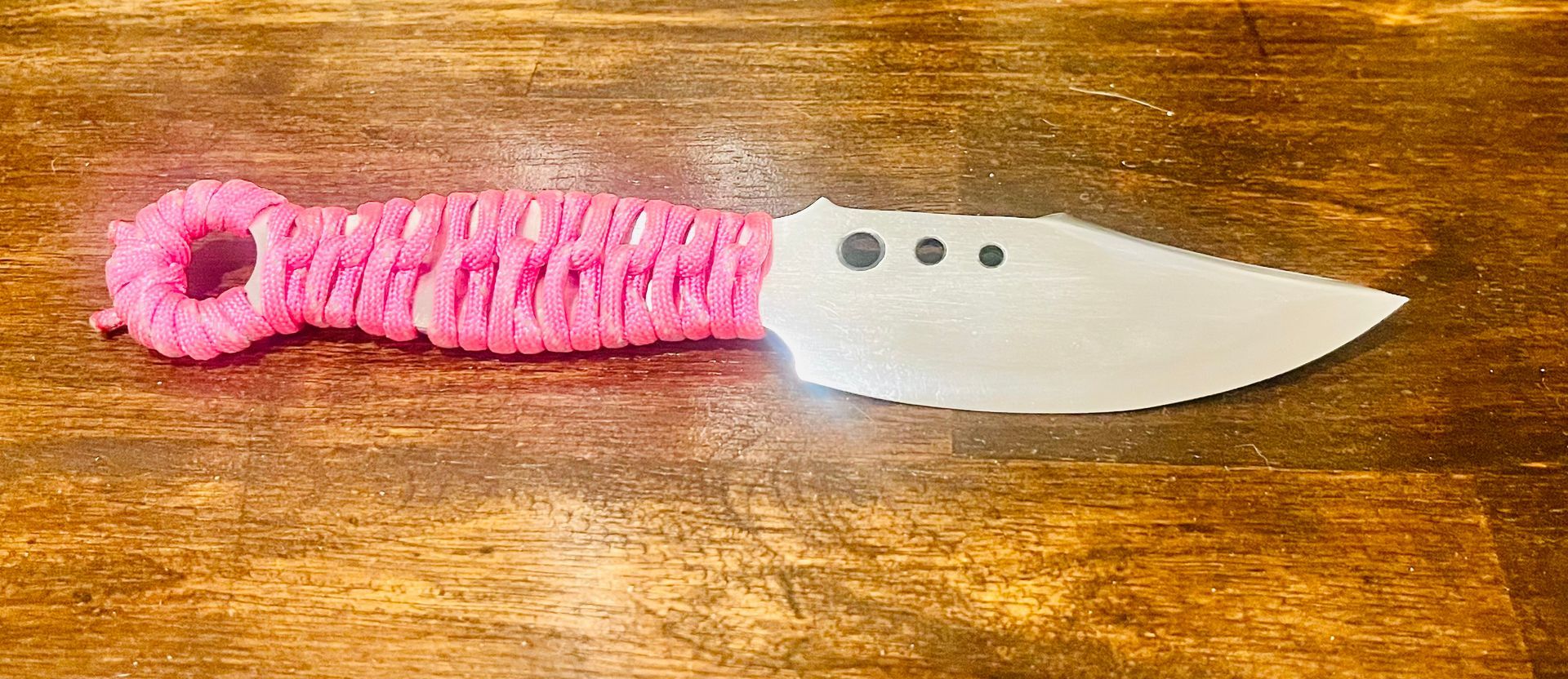

4" Bobcat Knife

4" E52100 Blade High Carbon Steel

Blue-Green Paracord Wrapped Ring-Tail Handle

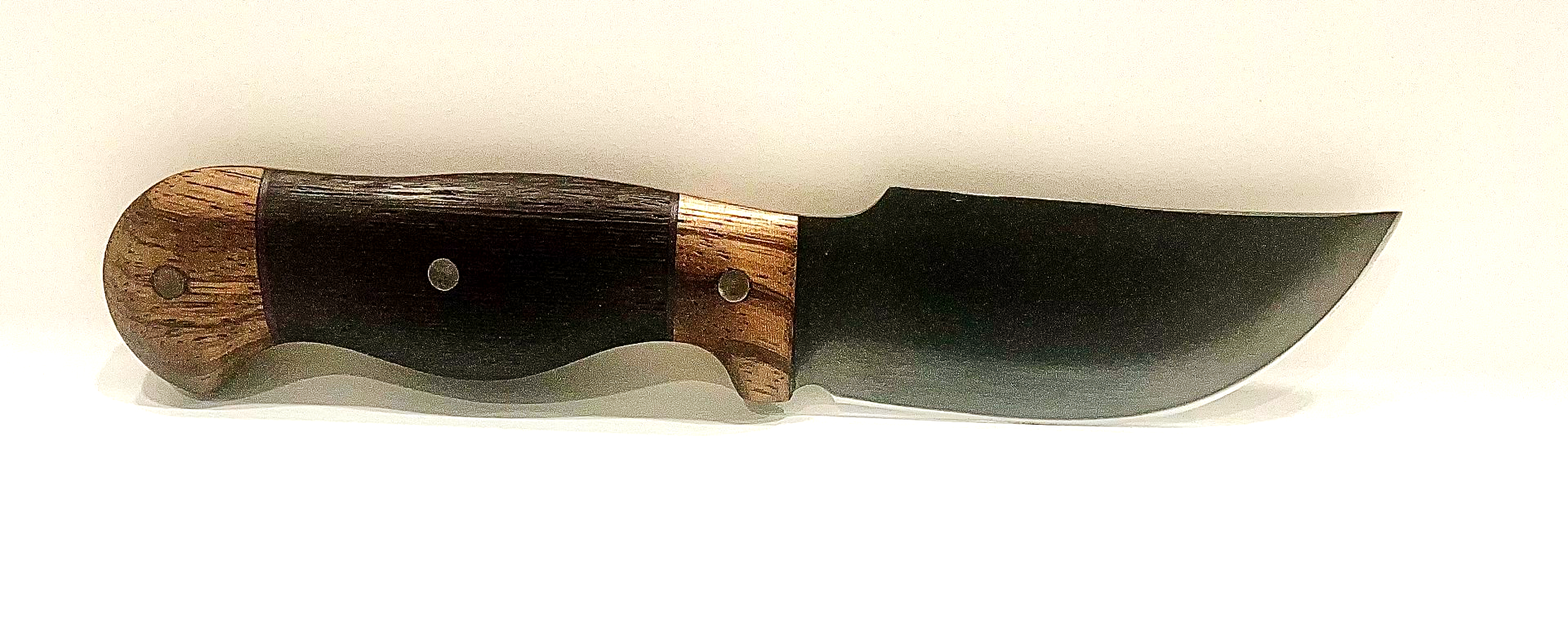

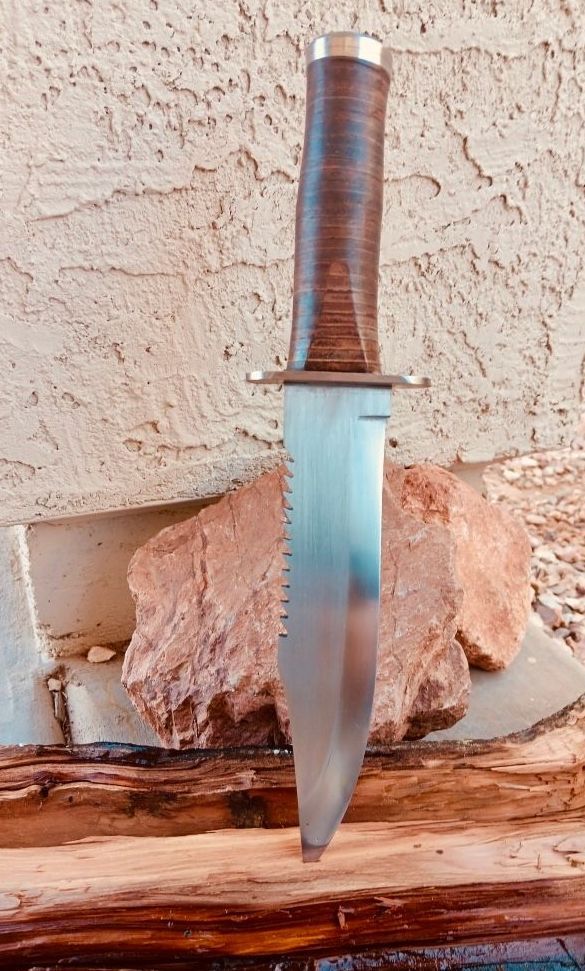

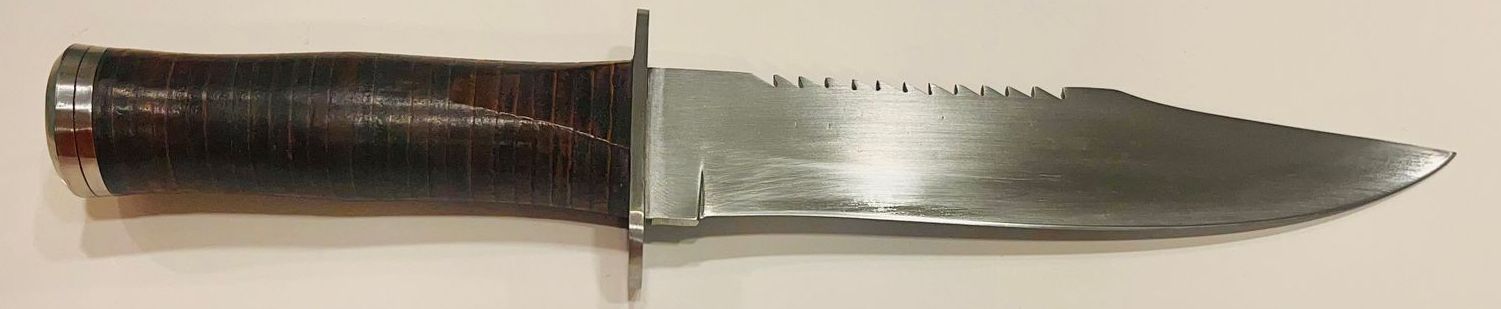

Big AL

Heavy Duty Camp Knife

One-of-a-Kind Custom, Strong, Sharp, Durable

Forged from 50+ Year Old Machinist File

Equally Strong Handle Made of Black Walnut Burl

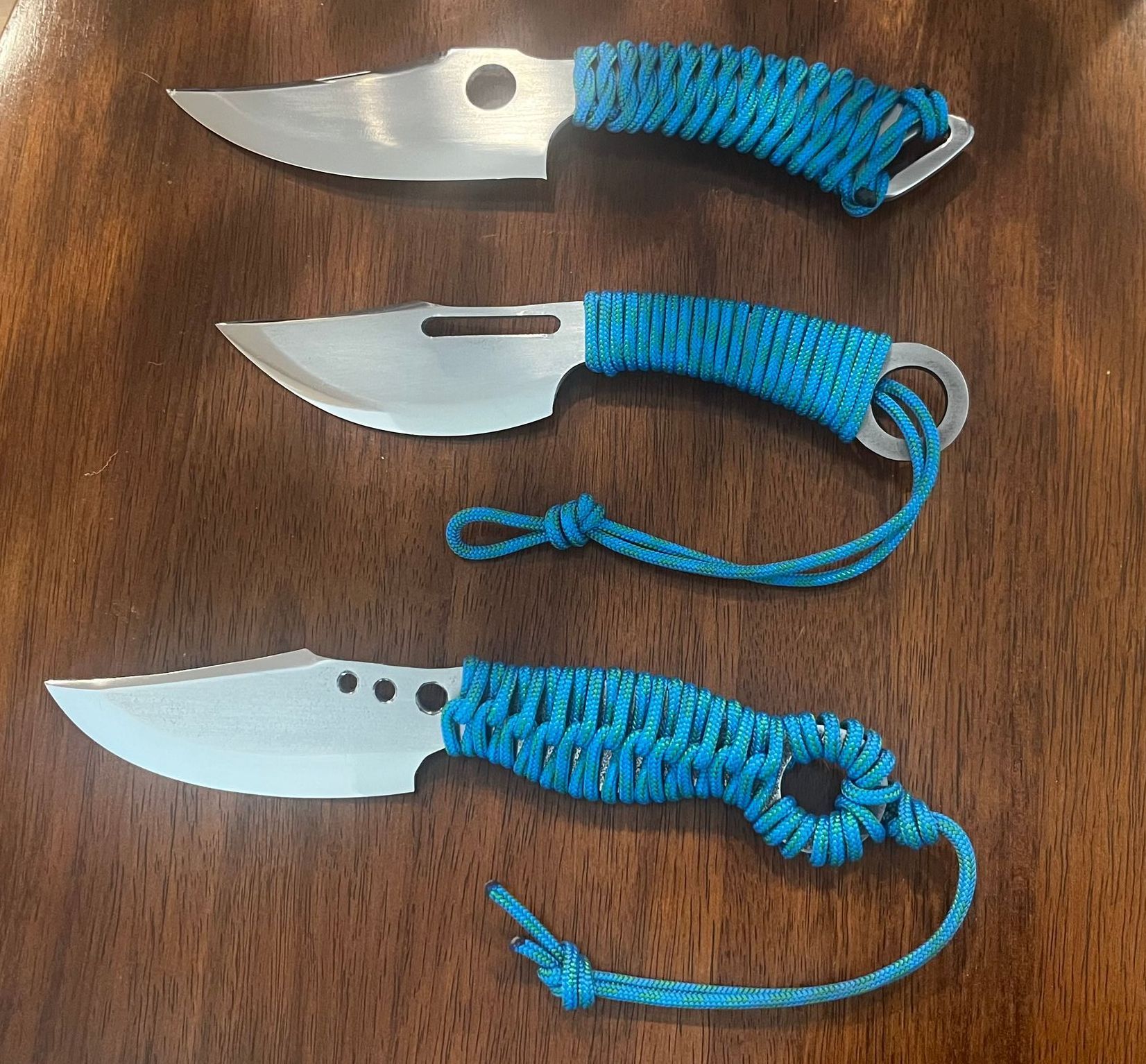

The Patriot & Junior Set

5" + 3" Skinning Blades

Father & Son Set

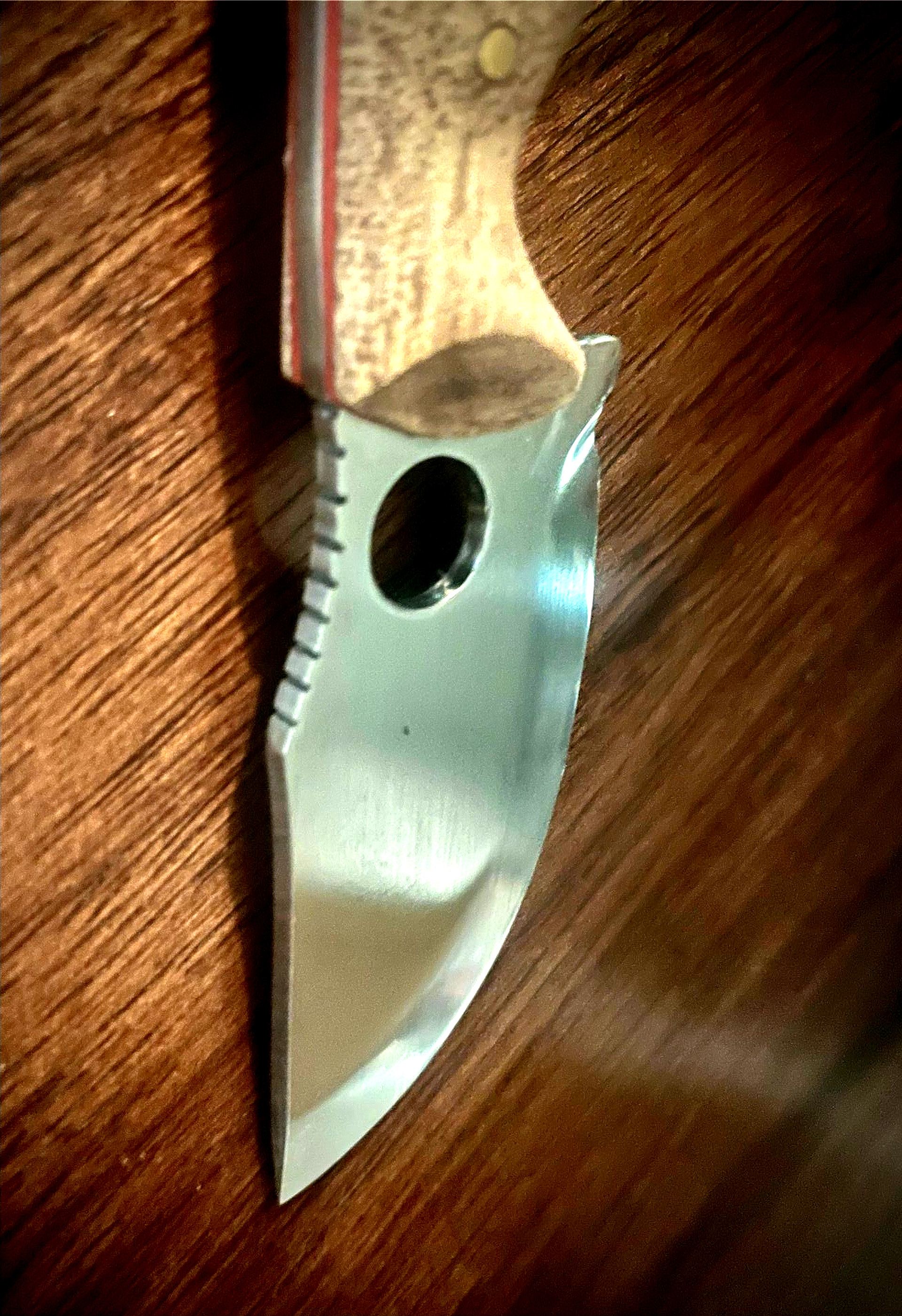

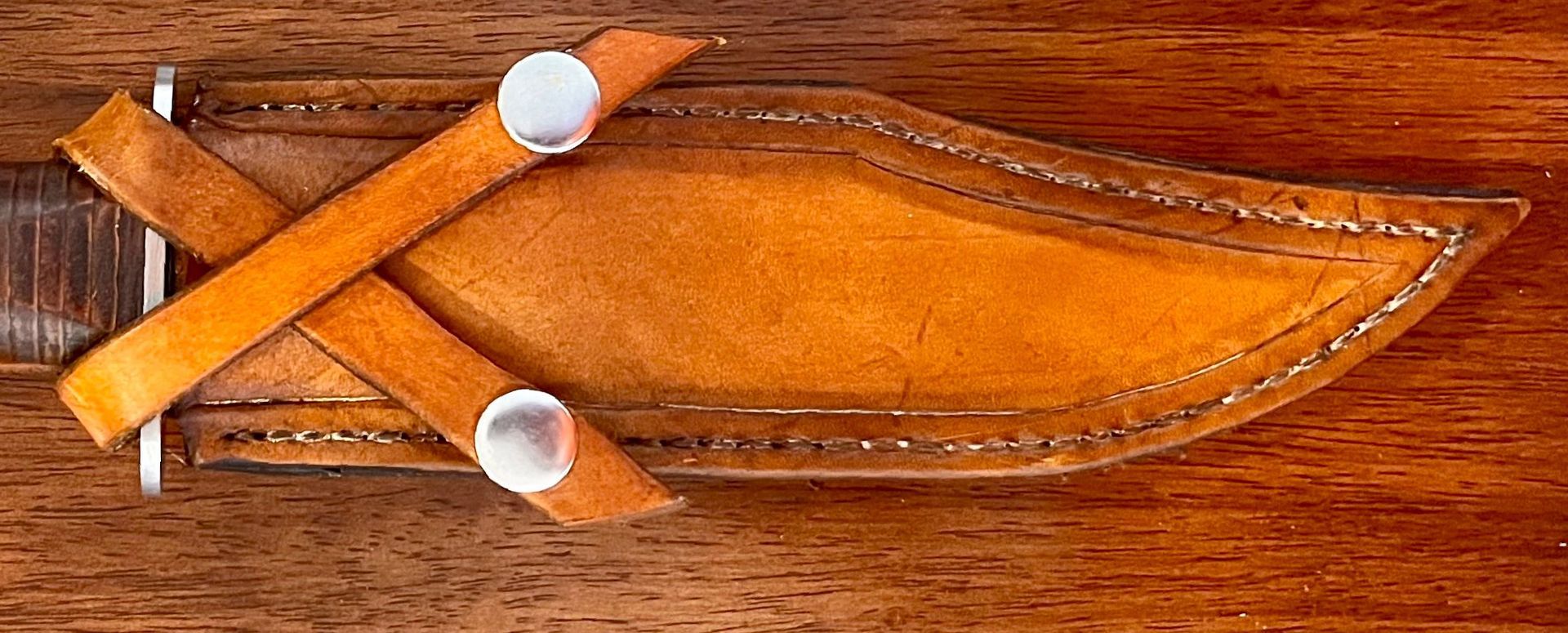

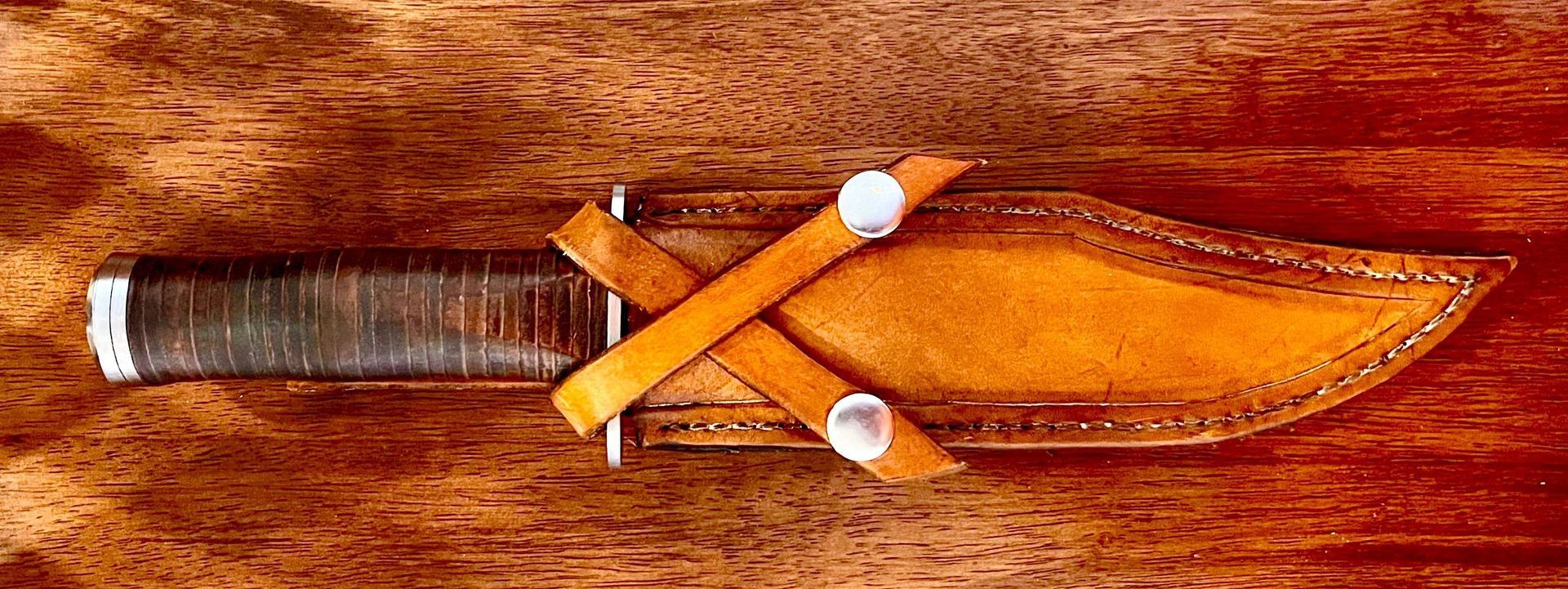

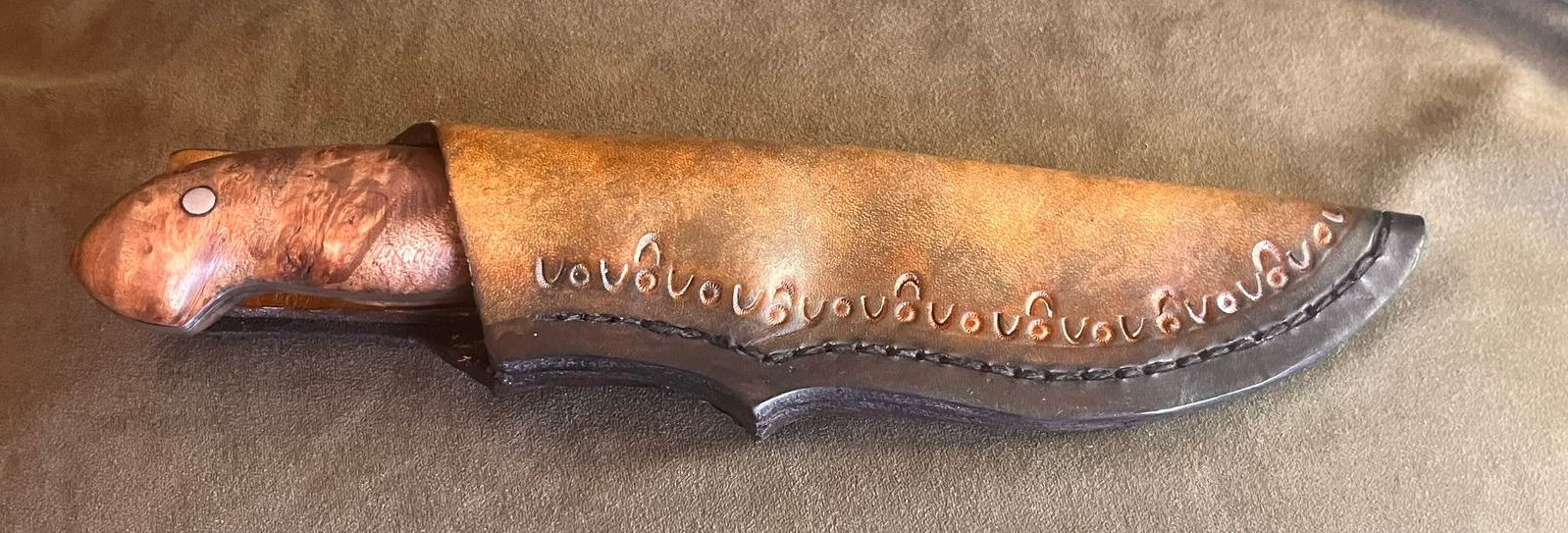

Heritage Pride

Custom Blade & Sheath Set

Special Request Native American Design

Hardwood Handle with Red & White Accent & Brass Pins

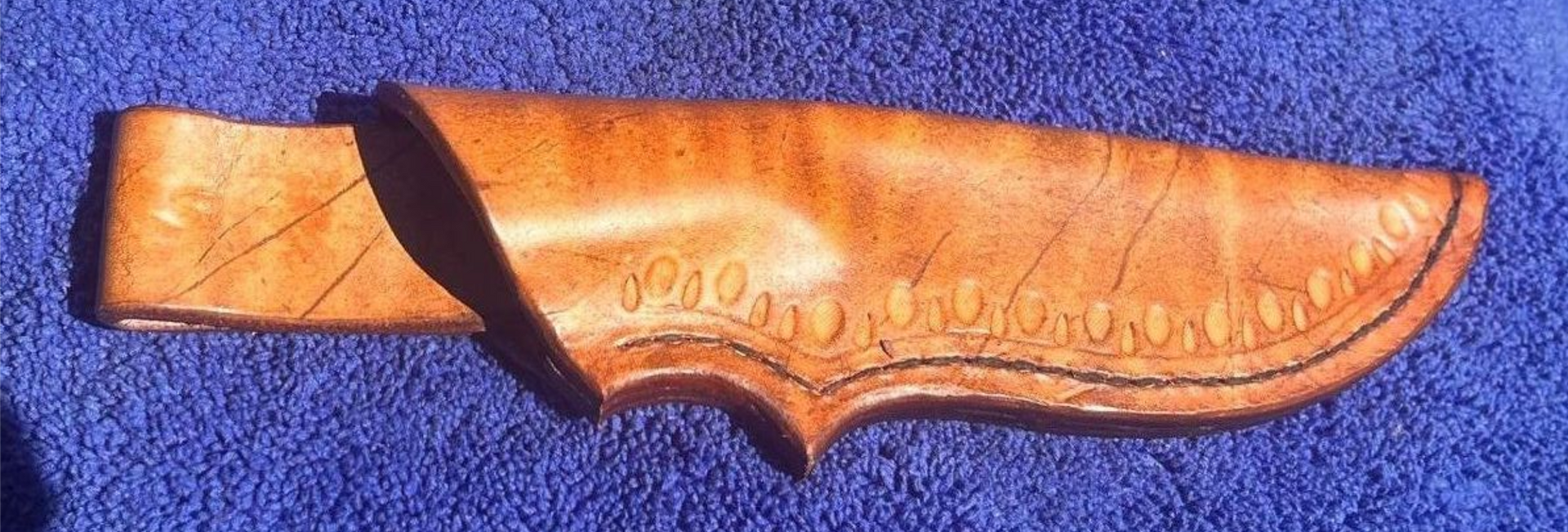

Custom Sheath Designs

Each JB Blades Design undergoes

4 Major Phases of Creation.

Follow along the steps of creation! See the quality & care that goes into

each and every custom made knife.

Phase 1

Concept & Design

The process begins with a concept of a basic design combined with practical field use and any customer specifications (size, material, colors, weight).

Concept

The genesis process. It all starts with an idea.

Drawing

Draw out and cut out a pattern design for the desired knife type.

Transfer

Transfer the pattern onto the desired type of steel and prepare for rough cutting the knife profile.

Phase 2

Profiling the Blade

Phase two is labor intensive. This is where the idea becomes realized.

Rough Grind

Using a hand held cutting wheel, roughly cut out the basic shape of the knife.

Grind to Finish Profile

Using the belt sander with rough grit sandpaper, grind to a finished knife blank.

Grind the Edge Profile

Measure and mark center line along the cutting edge, determine how deep the cutting should be, then grind to that line.

Rough Sand the Blade

Determine the type of finish (polished or satin), then file and sand to achieve the desired finish.

Drill Holes

Prior to heat treat!! Layout and drill handle pin hole locations, and any decorative or functional holes being incorporated into the blade.

Phase 3

Hardening the Steel

This is the process that gives strength, durability, and long life to your custom blade.

Forge

The forge burns at around 1800 degrees. Heat the steel to the proper temperature depending on the type of steel. Repeat a cycle of heat, remove, and air dry, in order to neutralize the steel, then heat one last time before the quench.

Quench

Quench the hot steel in preheated oil that is 110 degrees F. Leave the steel submerged for 1-2 minutes. Wipe off excess oil, then check for proper hardening with a round file.

Oven Temper

This step leaves the steel in a hardened state, but removes its brittle tendencies. Two cycles of 450 degrees, air cooling to room temperature in between.

Phase 4

Handle & Finish

Function meets art in phase 4.

Measure & Layout

Determine what materials will be included in the handle. Measure, layout, and shape for prefit.

Pin & Glue

Apply a clear 2-part epoxy to the blade and scales. Pin and clamp in place with precision.

Rough Shaping

Rough grind the basic desired shape of the handle.

Hand File and Finish Sand

Hand file and hand sand to a smooth, fine finish.

Polish

Using a buffer wheel and various grades of polishing compound, polish to the desired finish. Add stain or lacquer (optional).

Sharpen on Belt Sander

With 400 grit sandpaper, sanding is done at about a 20 degree pitch for general usage.

Razer Edge

Using a leather strop with polishing compound, take the burr off the edge with even strokes, both sides, until razer sharp.